Tooling Tooling

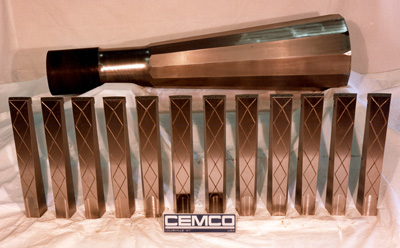

CEMCO machines are built to handle the widest possible range of part sizes by change of simple and inexpensive tooling. Tool change time varies from a few minutes on small machines to an hour or more on large units, and quick change fixturing is available as well as multiple die set-ups allowing several different size parts to be formed on the same tool. Tooling is normally made of carbon steel or tool steel. Cast iron and stainless steel are occasionally used, and on low production light duty jobs, try-outs, etc., wood and plastic have been used. CEMCO machines are built to handle the widest possible range of part sizes by change of simple and inexpensive tooling. Tool change time varies from a few minutes on small machines to an hour or more on large units, and quick change fixturing is available as well as multiple die set-ups allowing several different size parts to be formed on the same tool. Tooling is normally made of carbon steel or tool steel. Cast iron and stainless steel are occasionally used, and on low production light duty jobs, try-outs, etc., wood and plastic have been used.

1. How It's Done

2. The Advantages

3. What Kind Of Part Can Be Made

4. Limitations

5. Tooling

6. Controls

7. Operation

8. Flexibility

9. Consultation/Analysis

10. Investigate

|

|