Features of SizTech

- SizTech can help you to develop your product with shrinking technology

- SizTech can advise you, which applications are possible and which are NOT possible to shrink

- SizTech knows how to calculate the right shrinker for your application

- Our unique design reduces the friction in the system

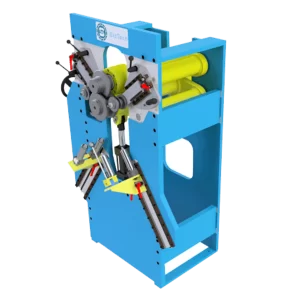

- SizTech offers proven, reliable machine design that guarantees high efficiency, long lifetime, and low maintenance costs

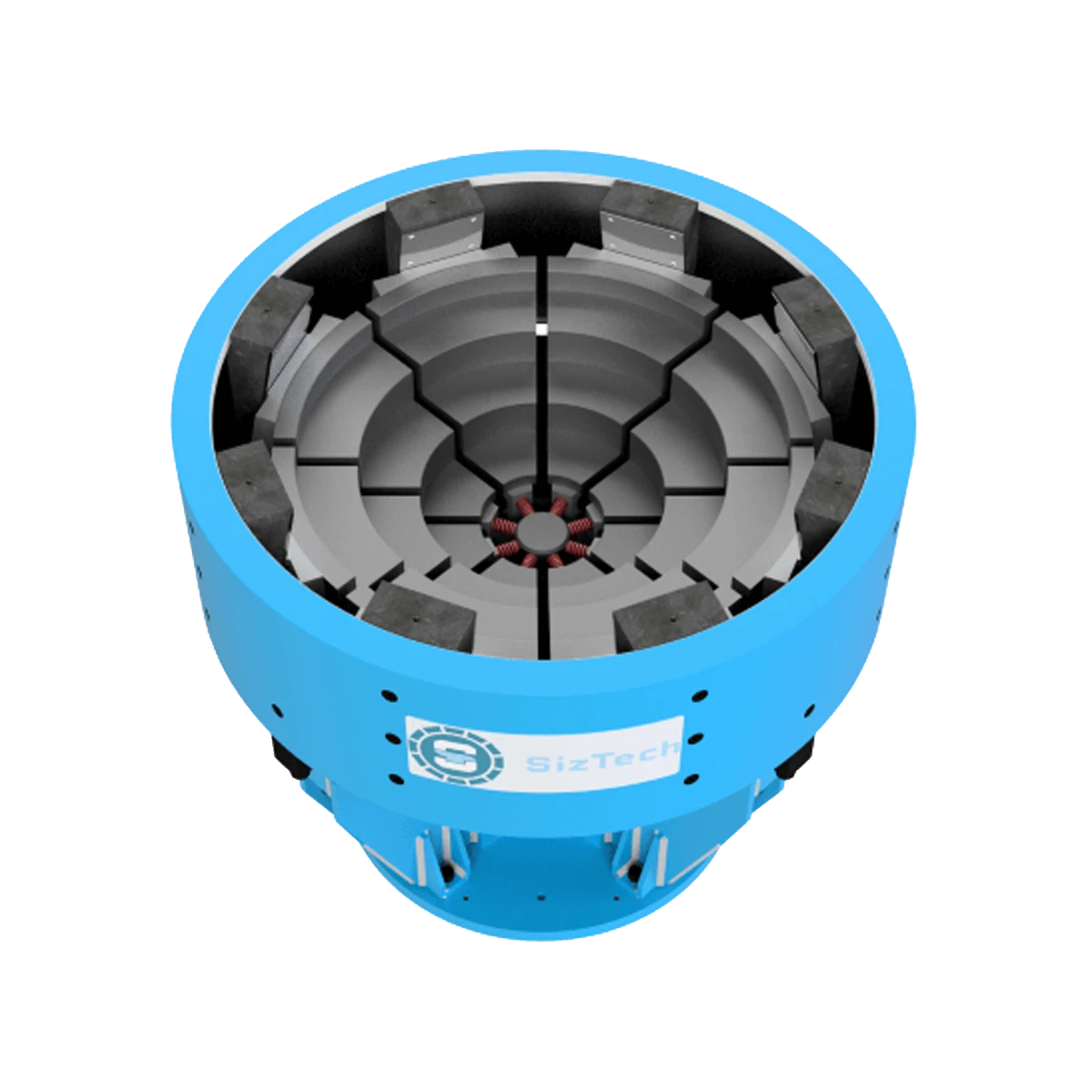

- SizTech designs and test tooling; tooling shares the same profile of the part which needs to be produced and is one of the most important parts in the Shrinker

- Quick change options for the tooling are available

- SizTech can also supply automatic loading and unloading systems

Shrinking Process – when the outside Diameter is of Importance

The shrinking process is, as expanding, the most economical means of forming and / or sizing a wide range of parts having a continuous cross-section.

Shrinking is the opposite of expanding, with the product being formed or sized from the outside diameter by exceeding the material yield stress during compression. This compression is used to reduce diameters. Forces act radially inward toward the machine centerline. The force required is higher than for the expanding process. The advantage is that improvements of the material properties are generated by a lower deformation.

Shrinking is preferred over other forming methods when the diameter of the part is relatively small and/or outside diameter accuracy of the finished part is critical.

Shrinking can eliminate or reduce machining operations and therefore reduce cost per part, especially when the outside diameter is of importance.

Metal Forming technology – Shrinking technology

We are experts for metal forming technology, especially for sizing and roll forming technologies. These are not so familiar within the industries we serve. We would like to change this as we believe in the benefits which include energy savings, machining reduction, quality, precision and more.